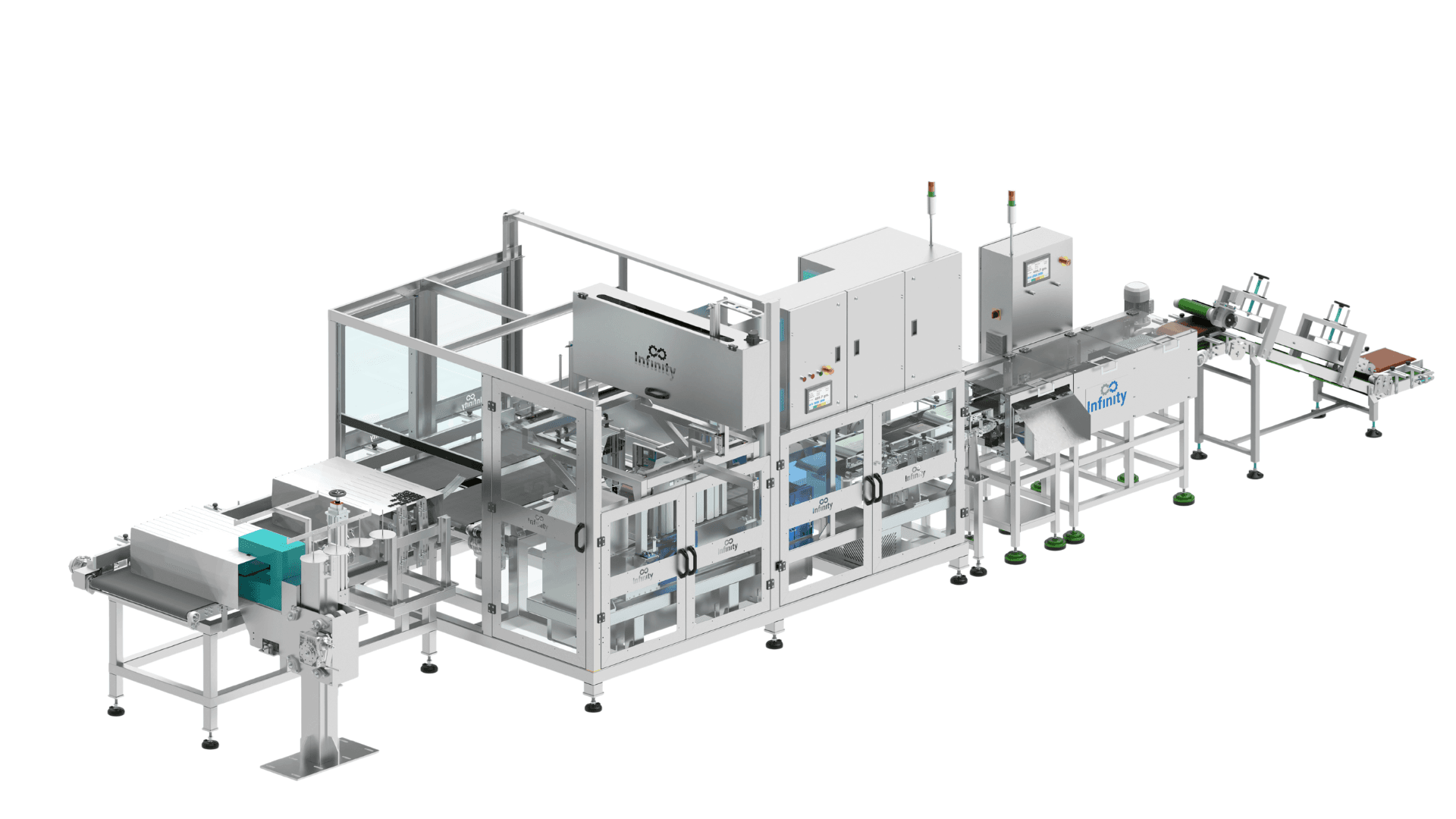

IBG-8 BaggingMachine

Quick Model Access

The IBG-8 is a high-speed bagging machine designed to collect products from VFFS or HFFS and transfer them to HDPE sacks. This advanced system handles large size pouches from 0.2Kg to 5Kg, featuring sandwich conveyor flattening, optional quality assurance through check weighers or metal detectors, and gate flap assembly for desired matrix formation. With sensor-based technology for exact product count and customizable solutions, the IBG-8 automates the bagging process while reducing labor costs and increasing efficiency.

Certifications

Watch Demo

IBG-8 Bagging Machine

Product Overview

The IBG-8 is a high-speed bagging machine designed to collect products from VFFS or HFFS and transfer them to HDPE sacks. This advanced system handles large size pouches from 0.2Kg to 5Kg, featuring sandwich conveyor flattening, optional quality assurance through check weighers or metal detectors, and gate flap assembly for desired matrix formation. With sensor-based technology for exact product...

Features & Capabilities

Professional GradeAdvanced Features

High-Speed Collection

Collects products from VFFS or HFFS and transfers to high-speed conveyor

Large Pouch Handling

Handles large size pouches (0.2Kg to 5Kg) with precision

Sandwich Conveyor

Products passed through sandwich conveyor for flattening and size reduction

Quality Assurance

Option to pass products through Check Weighers or Metal Detector for Quality Assurance

Gate Flap Assembly

Products assembled at gate flap assembly for desired matrix, count, and easy entry to HDPE sacks

Automated Bagging

Automates the bagging process with sensor-based technology for exact product count

Key Highlights

High-speed collection from VFFS or HFFS with seamless integration

Handles large size pouches from 0.2Kg to 5Kg with precision control

Sandwich conveyor system for pouch flattening and size reduction

Optional Check Weighers and Metal Detector for Quality Assurance

Gate flap assembly for desired matrix formation and product count

Sensor-based technology ensures exact product count and 100% QA

Automates the bagging process for increased efficiency

Significantly increases bagging speed and productivity

Reduces labor costs through automated operations

Advanced PLC-based control system for reliable performance

Multi-level password protection for security

Data report generation and production monitoring

Smart connectivity via Ethernet / MODBUS / Inverter protocol

High-speed operations with precision accuracy

7" Color Touch screen with 50 recipe function

Customized solutions based on client requirements

Universal integration with any primary packaging machine

Comprehensive production data display and transfer features

Related Models in pouch baler

IBL-500

IBL-500 Automatic Baler

IBG-8

IBG-8 Bagging Machine

IBG-H8-V8

IBG-H8 & IBG-V8 Bagging Machines

Ready to Get Started?

Get detailed pricing and specifications for IBG-8 Bagging Machine

Transform Your Packaging Process Today

Join 800+ satisfied customers who have revolutionized their packaging with our IBG-8 Bagging Machine solution.